How 3D Printing Is Changing the Construction Industry

If you look up 3D printing on the Internet, you will see that just about anything can be printed, from shoes to cars, prosthetics and, in the near future, they will print human organs for transplants. So, why are we not printing houses?

In his Ted Talk, University of Southern California professor, Behrokh Khoshnevis, creator of Contour Crafting, said, “If you look around yourself, pretty much everything is made automatically today—your shoes, your clothes, home appliances, your car. The only thing that is still built by hand are these buildings.” Several companies around the world are working tirelessly to change this.

The Basics of 3D Printing

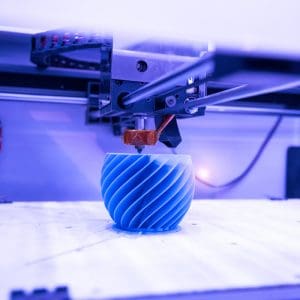

The process of printing in 3D starts with an electronic model of what you’d like to print, accomplished by creating the model with special software or by scanning an object and then printing a copy of it. Google and Microsoft are working on technology that will allow you to take a 2D photo, which will then create the model for a 3D printer.

Building one layer on top of another layer until the object is completed is the simplest way to explain 3D printing. And, since high-quality 3D printers can use almost any substrate, from plastic to soil or even concrete, many envision bringing a large 3D printer to a job site one day in the near future, plugging it in and printing out a house.

Current Changes to the Building Industry

Every part of a construction project is custom made to meet the needs of the end user and the constricts of land being built on. Sometimes, a particularly shaped part is needed, and a 3D printer makes it easier and less expensive to produce. Some engineers estimate that using this technology will reduce the cost to build a home up to 50% due to reduced costs for construction materials and lower labor costs.

These printers are very accurate and can produce items with lower materials usage and little to no waste. Green construction can be realized by using less lumber and less resources. Project planning is greatly improved by using the 3D printer to create models of the structures before actually swinging a hammer, saving time and avoiding delays, minimizing problems before the build.

Limitations of 3D Printing

The largest limitation of using 3D printing in the construction field is the cost of building a printer that can print very large structures, cost prohibitive to most contractors. The printer is often used to print items offsite like walls and floors, transported to the job site and assembled by hand with other materials.

The printer also only prints with one material, so other materials must be assembled by hand to make it all work. The printing makes the most sense currently by printing small items, custom pieces, special materials and one-off projects that otherwise would be cost prohibitive in the traditional way. Regulations are hard to control and it is hard to pass inspections — because there are so many ways and materials to print with, quality control is an issue and could end costing more in the end.

Not So Distant Future

Currently, engineers and architects see this technology as another tool they can use to make the building process easier for them for specific portions of their projects. The industry isn’t quite ready to utilize a 3D printer to build an entire structure at this point; however, all new engineers and architects should be learning 3D programming processes to keep pace with the evolution of the building industry.

The largest building made using a 3D printer is located in China. In their modern construction, they use 3D printers to print the core materials and assemble the pieces on site by hand. Still, they claim the 3D construction applications are saving both time and money. In Amsterdam, they have been researching utilizing a 3D printer to fabricate a steel bridge, and construction is set to begin this year.

In Australia, they recently unveiled a tree house that was created fully using a 3D printer — they claim there is no reason they could not also print a full-size home. The thought that 3D printers could help under-developed countries all across the world and provide housing for so many that have never had it before exemplifies that the future for the construction industry holds great possibilities that we never thought possible before.

Receive the latest industry insights from the evōk team in your inbox by signing up for the evoker, our monthly newsletter or contact us to explore ways we can partner.